designed by AI, perfected by scientists

plasma-printed batteries

unprecedented fused layers of metal & carbon super-materials

cheaper, better, safer EV

batteries manufacturable NOW

Technology

that enables manufacturing an entirely new range of earth-friendly high performance batteries

Mechanically interlocked molecules forming extremly strong bonds to the base substrate, as well as amongst the active material

Powering the

Future of Energy

Reduced environmental Impact (less energy, no toxic solvents & binders)

Nanoloy's

Plasma Printer

Proven tech in

another industry, highly

scalable, designed and manufactured by Nanoloy

Redesigning

battery chemistries

Game-changing implications for battery manufacturing

Revolutionizing Battery Technology

New deployments

under way with international partners

Empowering EVs to drive safer & longer

Game changing implications for

next gen batteries

Why transformational?

Breakthroughs in solving new,

earth-friendly battery chemistries

Many new battery inventions are languishing in labs because they can not be manufactured at scale. Nanoloy can turn the table

Superior interfacial metallic & carbon bonds

New material composites delay the degredation of the anode and cathode, dramatically increasing battery performance

Nanoloy’s thermally fused bond of the electrode particles eliminates a major source of inefficiency that limits the life and performance of lithium-ion batteries

Step Change in production cost, quality and speed

Nanoloy’s mature and highly scalable plasma printer is expected to make mass production of next generation batteries viable without decades of R&D

We take pride in our numbers

21

years of experience in plasma deposition

800

mAh/g specific capacity of our Boron Anode

1200

mAh/g specific capacity of our Silicon Anode

<$10M

needed to reach pilot production

5

battery product development partners

Our products

(in development)

graphene armoured

current collectors

silicon anode 60% Si

boron anode 60% B

multi-layer graphene

99.94% purity

The Technology of Nanoloy's plasma coating process has a great potential in the field of battery production and can be an enabler for future cell technologies

Professor Achim Kampker

Chairman, PEM Motion, Germany

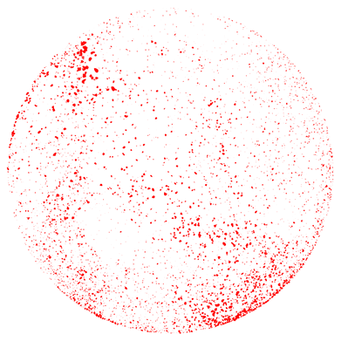

Cross sectional analysis of the Nanoloy 95% graphene and 5% PVDF (polymer) on the aluminium foil shows the carbon bond directly to the aluminium oxide layer forming strong mechanical bond to the base substrate. The carbon and polymer are present in a tighty bonded structure

Terry Munson

CEO, Foresite Inc. USA

For most practical applications, this LMFP cathode works close to its theoritic limit. We attribute this good performance to the high quality of the LMFP material, the low interfacial resistance of the graphene coating layer and the low binder content of the dry processed cathode.

Andras Kovacs

CTO, BroadBit Batteries OY, Finland